Hillco Technologies Pivoting Spout

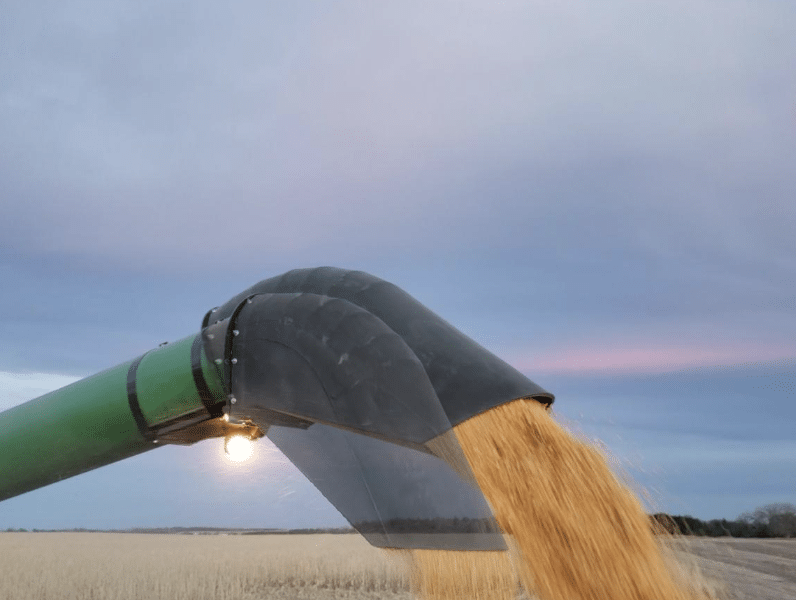

The Hillco Pivoting Spout is an aftermarket attachment designed for John Deere combines. It enhances the unloading process by providing increased flexibility, precision, and efficiency.

The JPS1720 model of the Hillco Pivoting Spout offers several improvements. The injection mold boot has been redesigned to seamlessly integrate with the factory spout, ensuring durability. The spout tip has a smaller diameter, enabling tighter spreading and more accurate pouring.

The latest design of the Hillco Pivoting Spout provides a total pivot capability of 37°, allowing for increased unloading possibilities. It can pivot downward up to 23° for nearly vertical pouring and upward up to 14° for extending grain throw beyond the standard boot.

Experience Enhanced Unloading Efficiency & Precision with the Hillco Pivoting Spout!

The Hillco Pivoting Spout for John Deere combines, now available in the improved JPS1720 model. Discover the simple features and capabilities that can level up your unloading process.

What’s new in the JPS1720? Firstly, the injection mold boot has been redesigned into a single seamless piece, closely resembling the factory spout. This seamless integration ensures durability and longevity. Additionally, the spout tip now boasts a smaller diameter, allowing for a tighter spread and more accurate pouring, without compromising volume. The actuator remains conveniently located on the side of the auger, away from potential unloading hazards.

The latest design of the Hillco Pivoting Spout offers an increased total pivot capability, expanding from 33° to an impressive 37°. This extended range of motion provides new unloading possibilities. Starting from the stock boot position, you can achieve a downward pivot of 23°, enabling nearly vertical pouring. Moreover, the 14° of upward pivot allows for a grain throw of over three feet beyond the standard boot.

Controlling the pivoting spout is effortless with the foot rocker switch, which can be mounted anywhere on the cab floor for convenience. Whether unloading on the go into a grain cart or topping off a truck, the pivoting spout allows you to make the most of limited space, increasing efficiency and productivity.

Worried about compatibility? The Hillco pivoting spout is designed to fit any 17″ high unload rate auger, which can be found on various John Deere combine models such as the 60 and 70 series, as well as the S series equipped with 17″ unloading augers. We recommend keeping the stock grain flap in the auger to maintain grain containment during unloading.

The Hillco Pivoting Spout is competitively priced, starting at $2,200 (excluding freight charges). To place an order or gather further information about this exceptional product, our dedicated sales team is ready to assist you. Contact us at 800-937-2461 to get any of your questions answered as well as a personalized freight quote.

Upgrade your unloading operations with the Hillco Pivoting Spout and experience heightened efficiency and precision. Don’t miss out on the opportunity to optimize your farming practices. Order your JPS1720 today! Limited stock available!