Hillside Leveling System (27%)

If you harvest in the hills with a John Deere combine, there is no better investment you can make than equipping your John Deere combine with a leveling system from Hillco Technologies.

Hillco Leveling Systems

John Deere Hillside Models

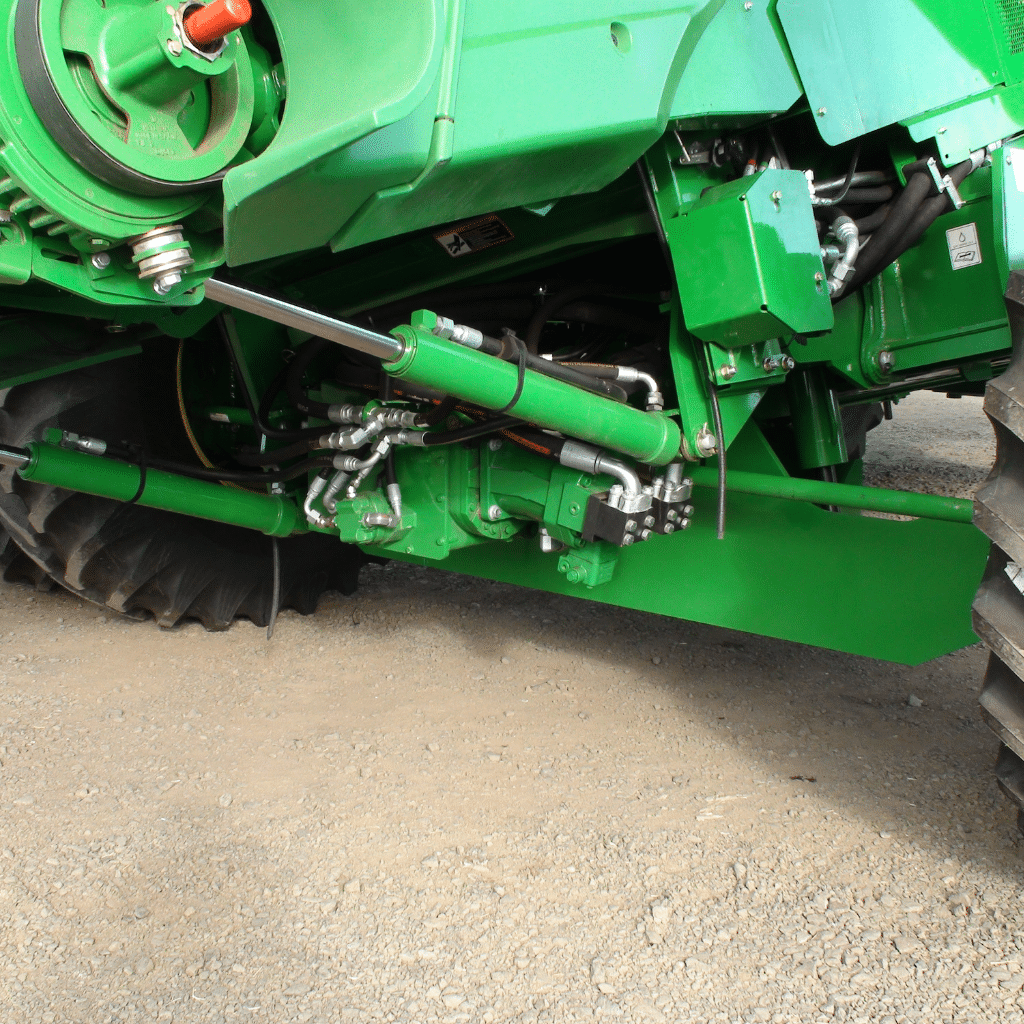

Hillco Leveling Systems are packed with a long list of industry leading features and benefits such as true bolt-on design, fully automatic variable speed leveling, and fully automatic header height and lateral tilt control.

Other benefits include increased hillside capacity, reduced hillside grain loss, improved sample quality, and comfortable hillside operation. Additionally, Hillco guarantees that your combine’s original John Deere warranties will remain in full effect after installation of your Hillco Leveling System.

Hillco Technologies offers a broad range of leveling systems specifically designed to maximize STS & S Series combine’s performance in all terrain.

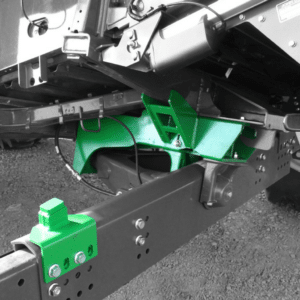

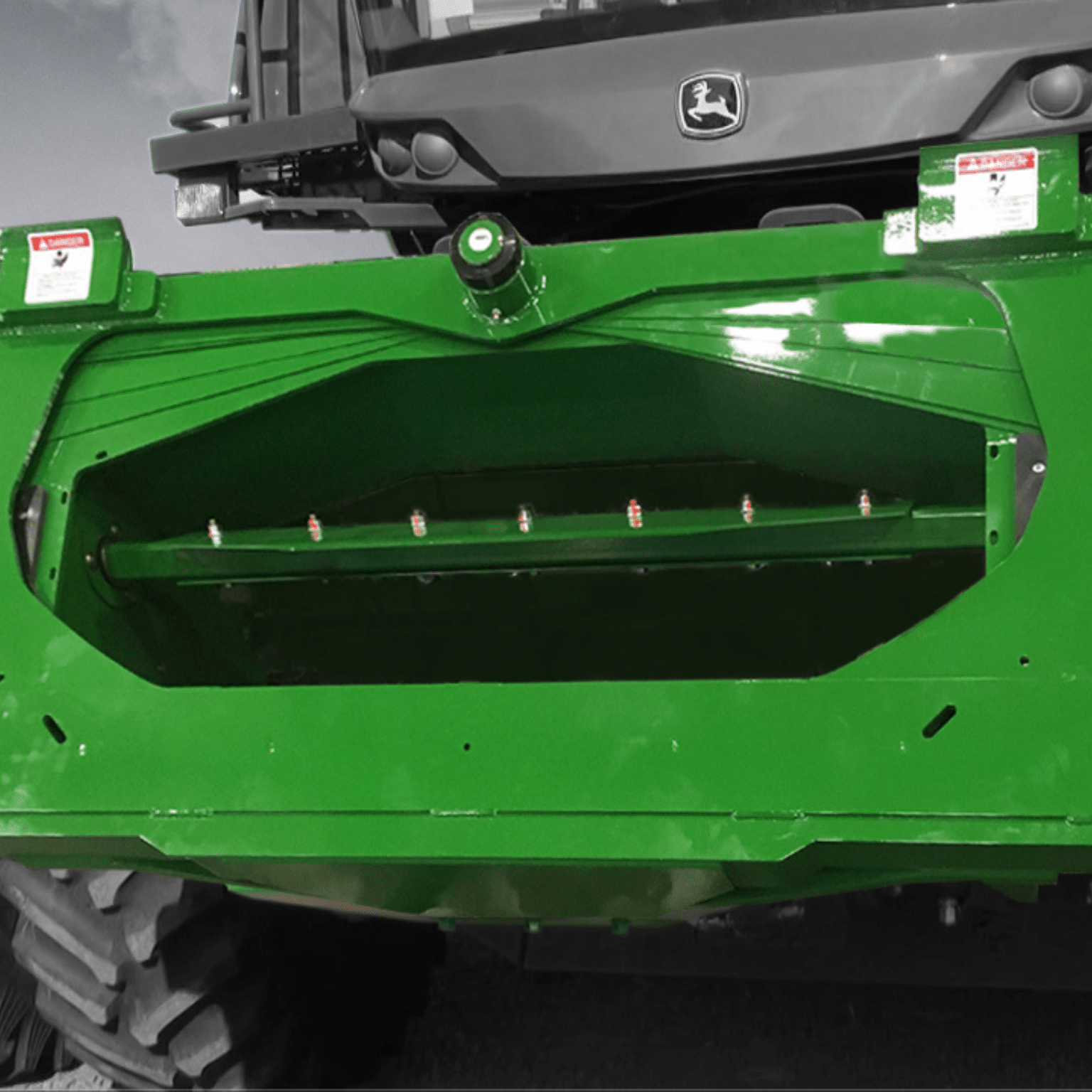

Header Adapter and Header Tilt

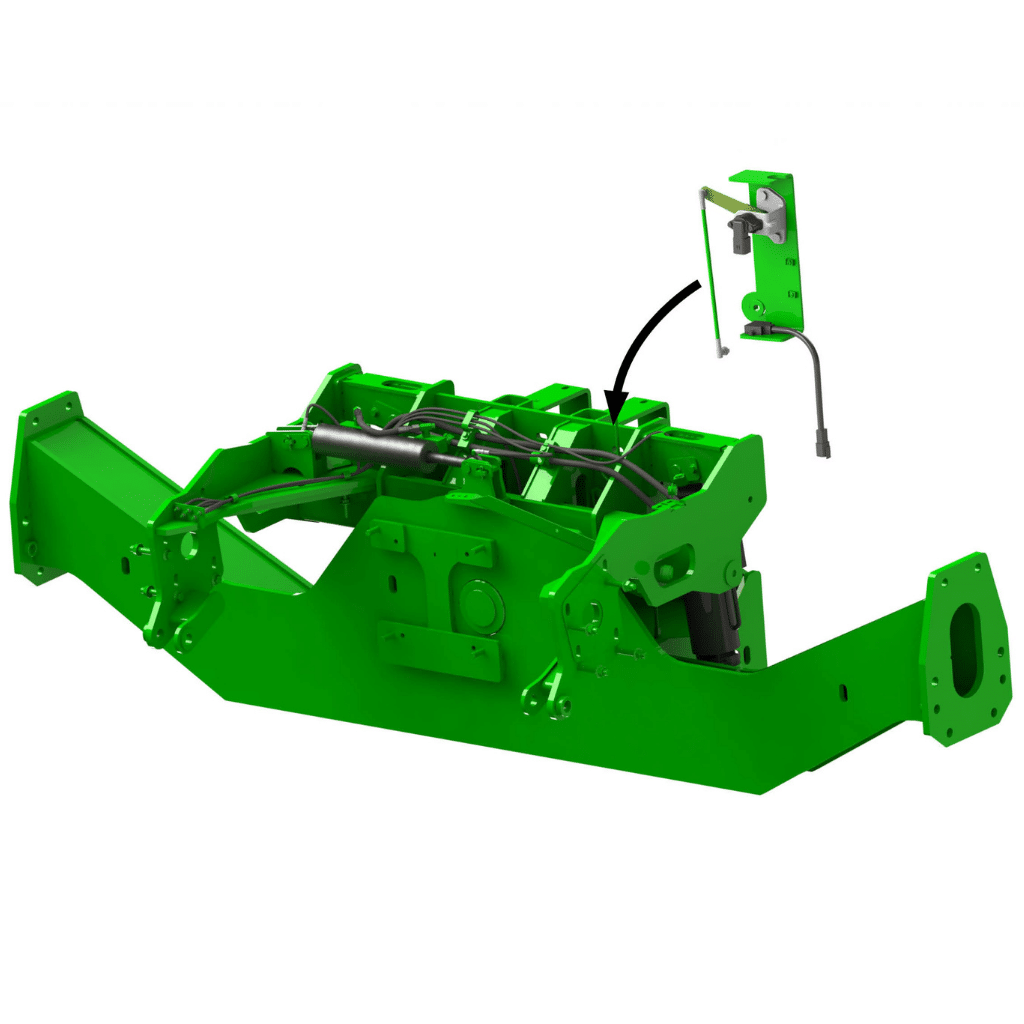

The Heart Of Every Hillco Leveling System

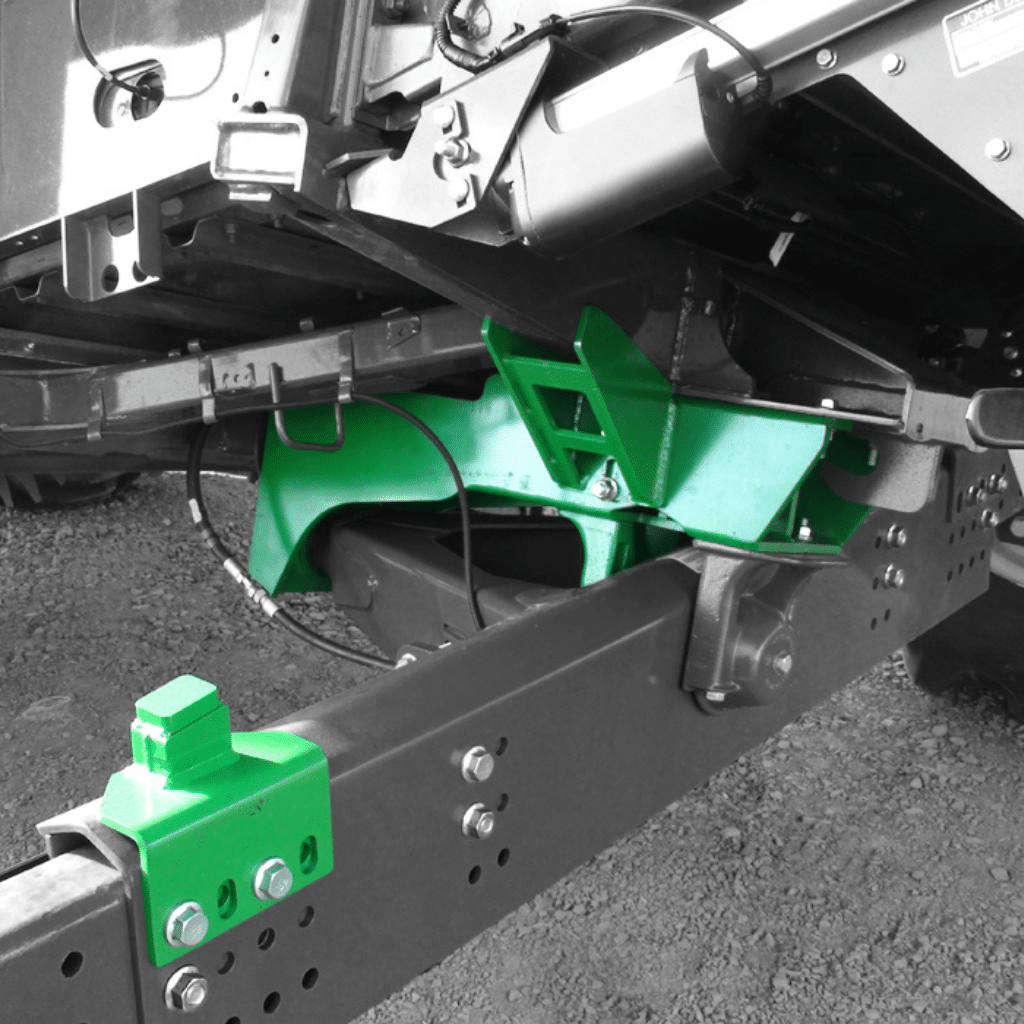

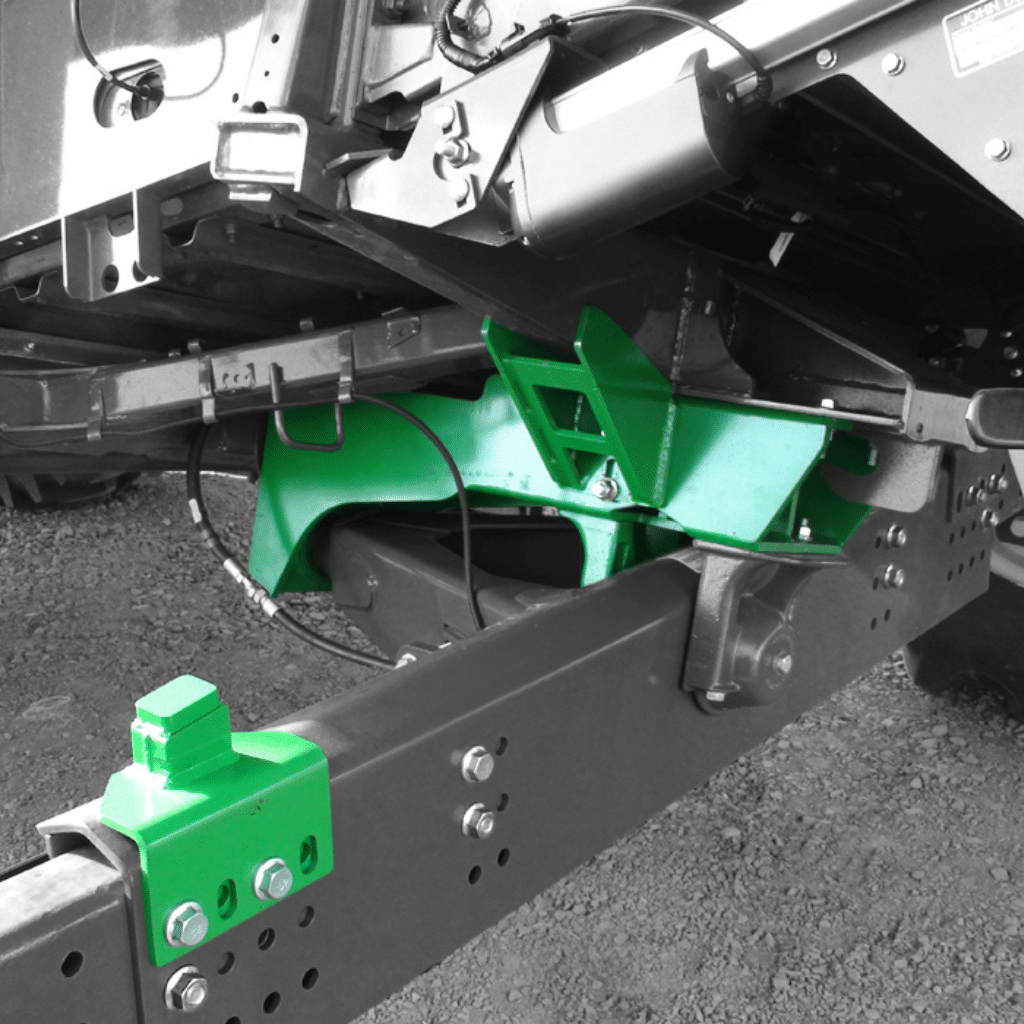

Rear Drop Axel

Crop Feeding System

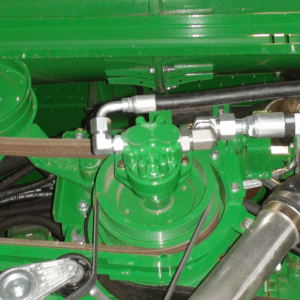

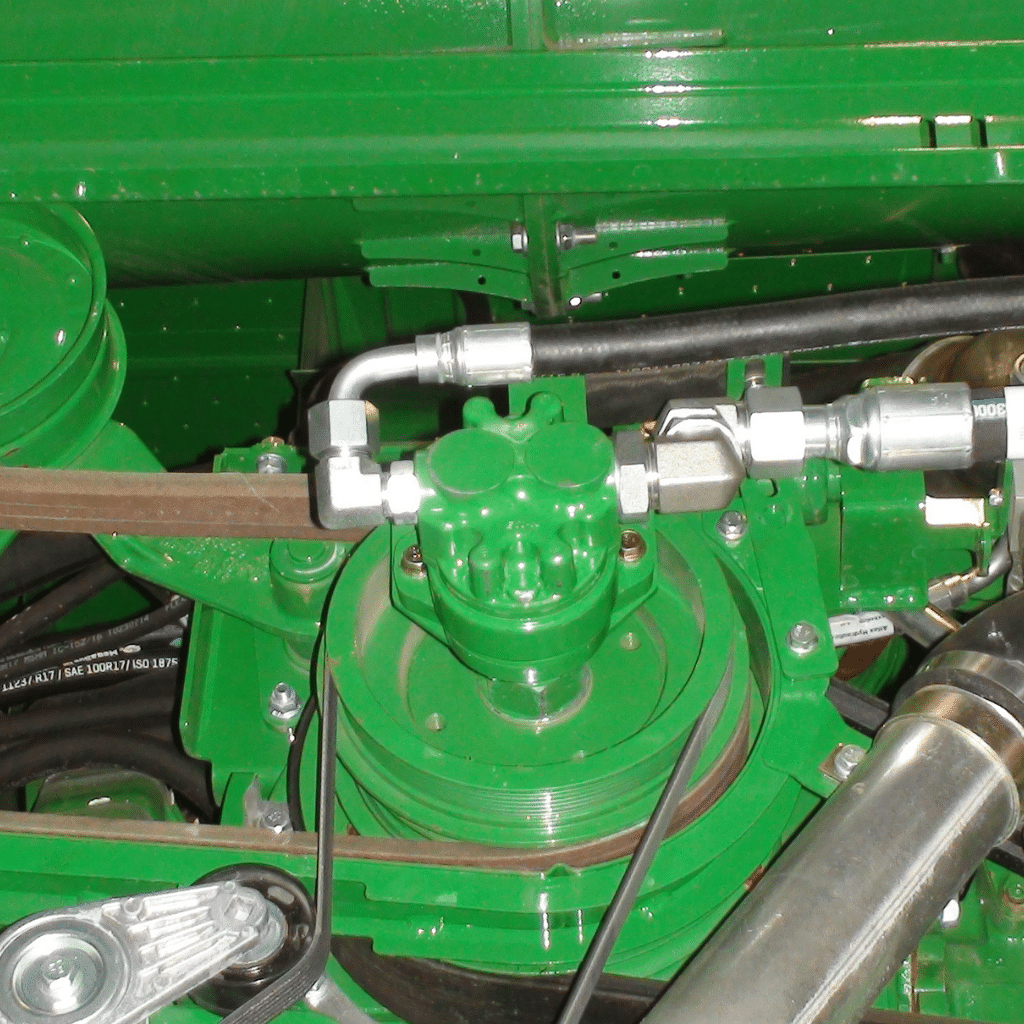

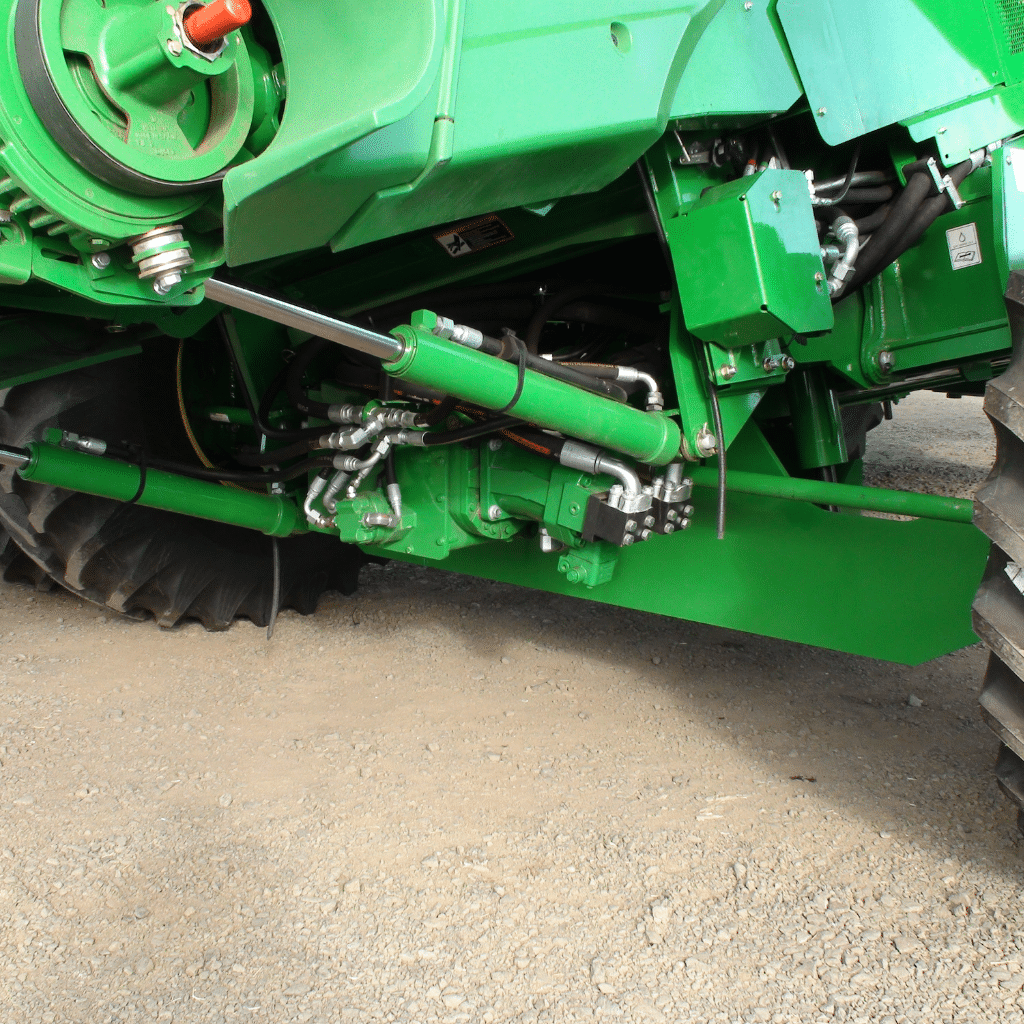

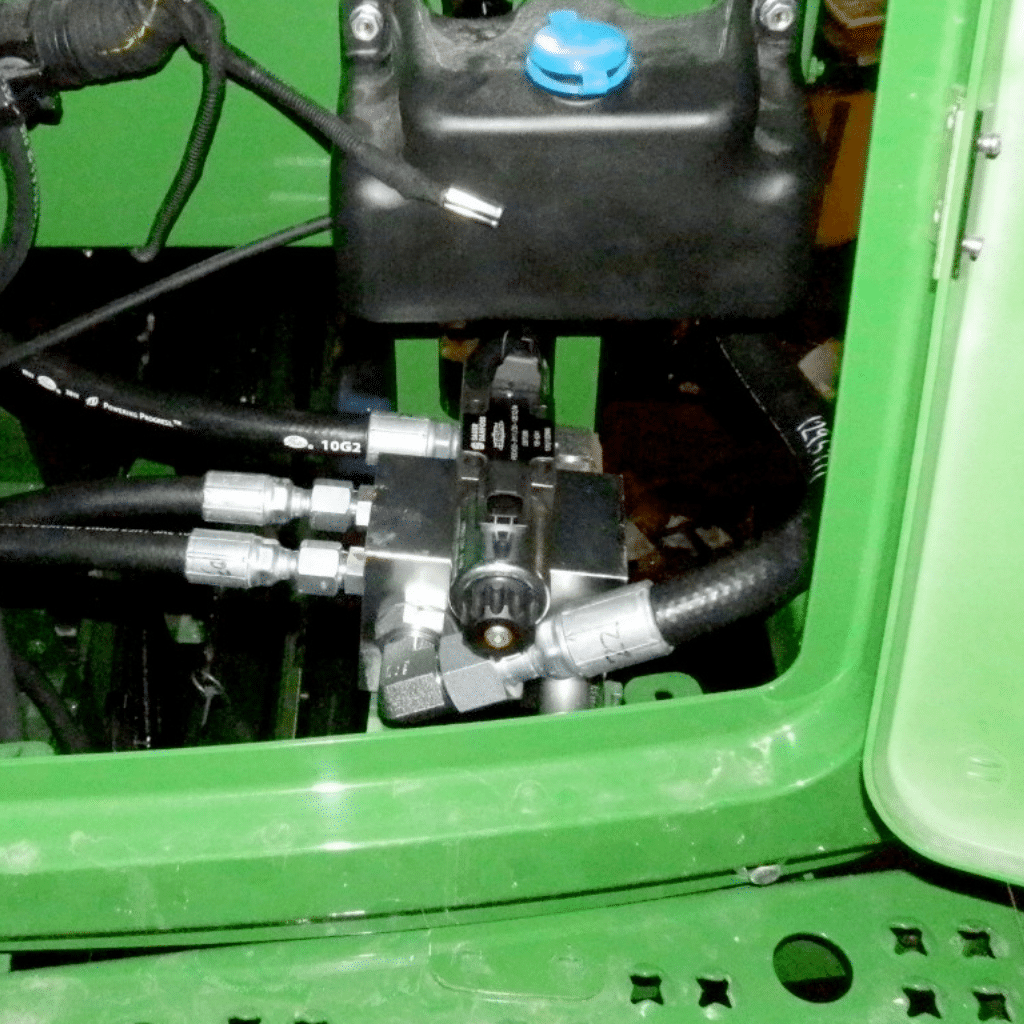

Hydraulic Pump- S660, S670,S760 & S770

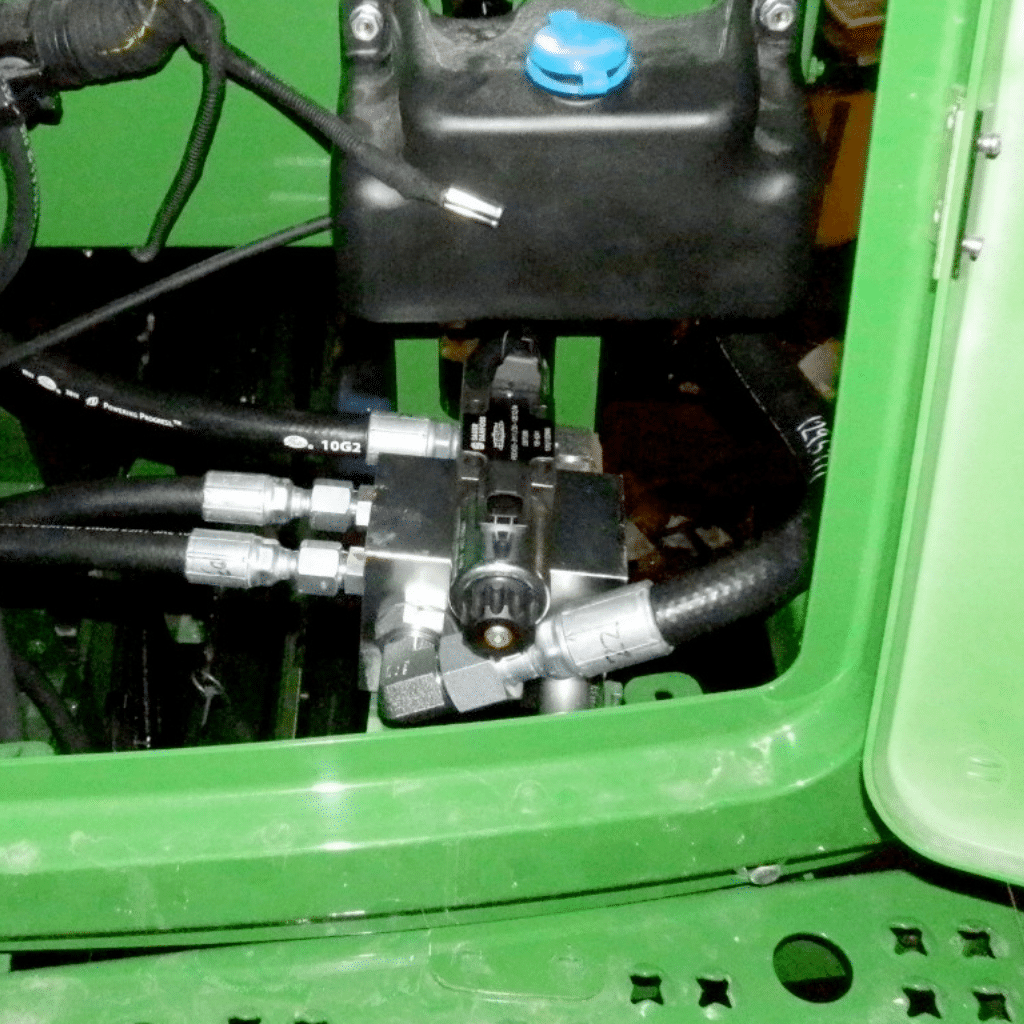

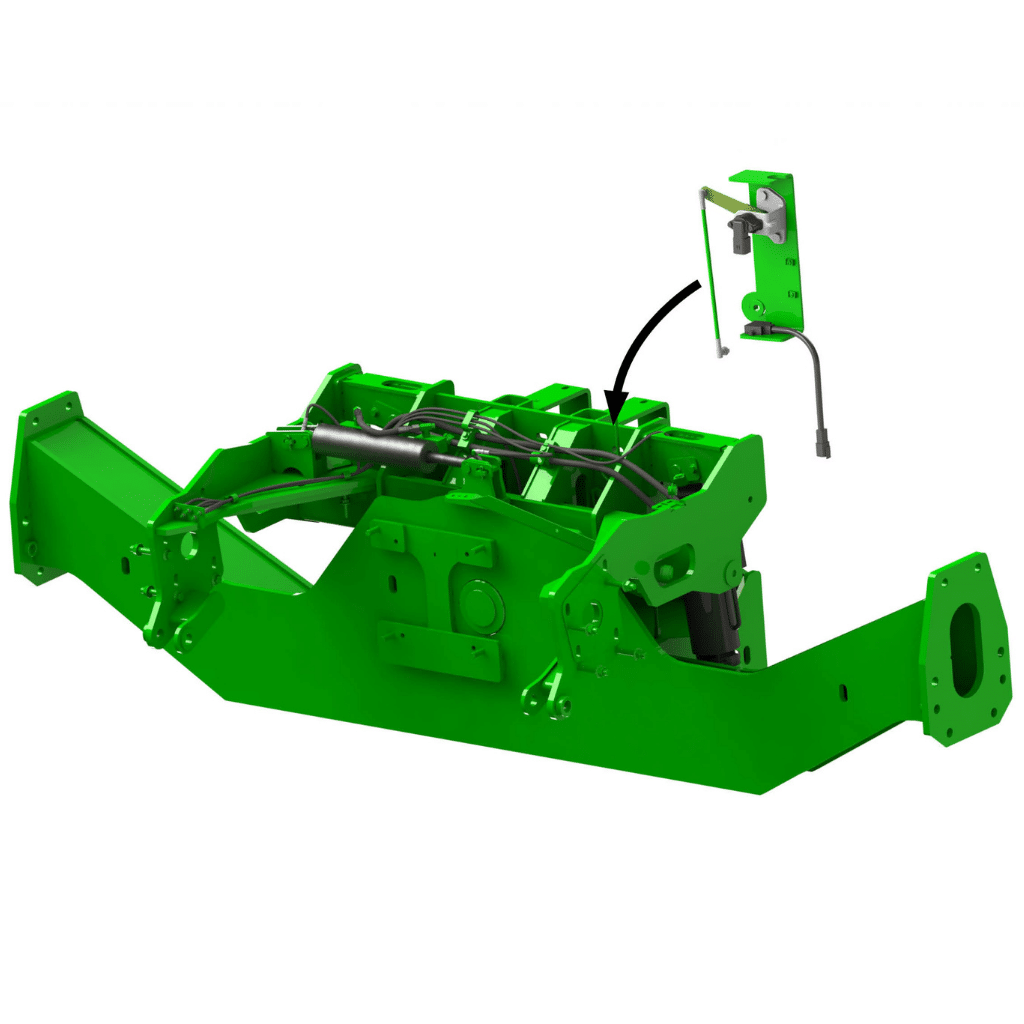

Maximum level Potentiometer

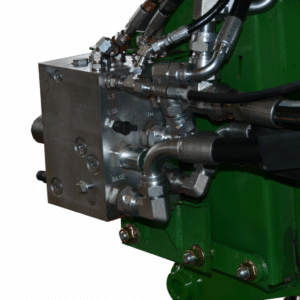

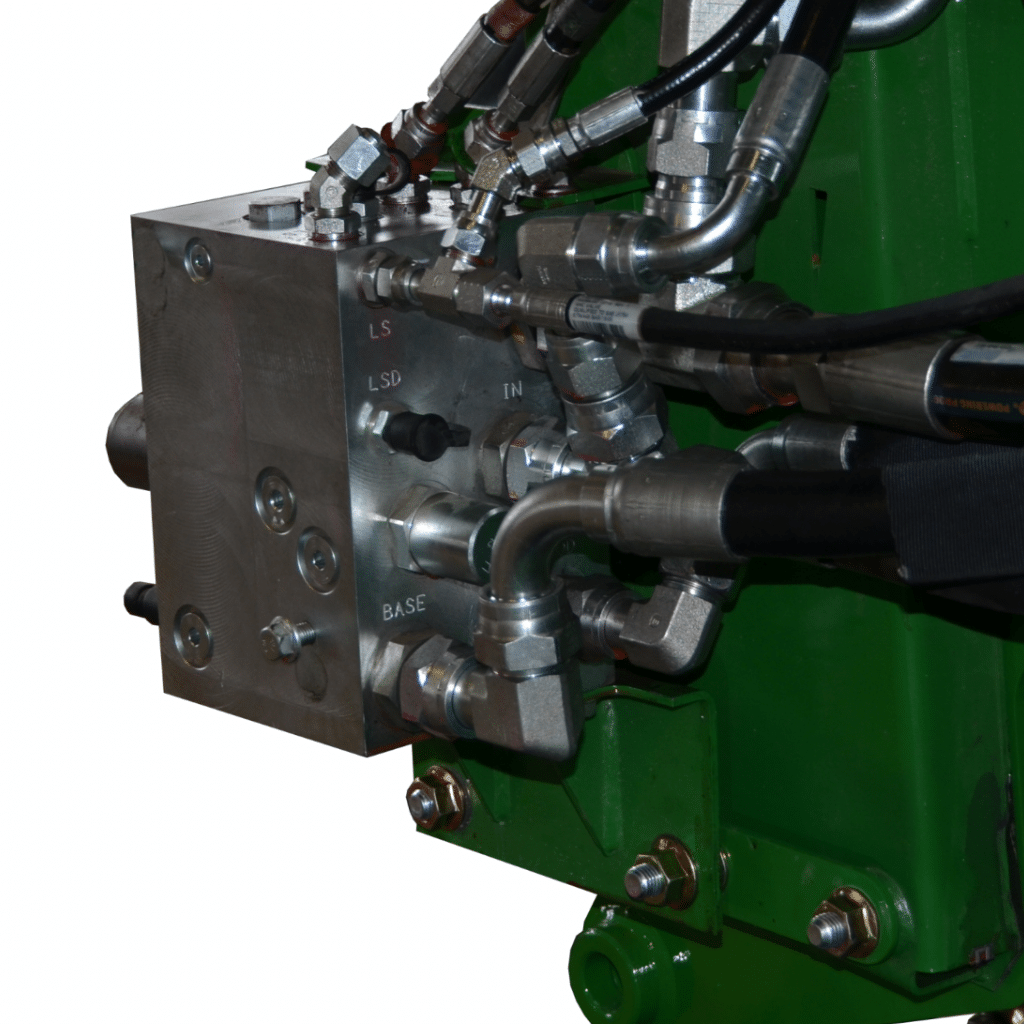

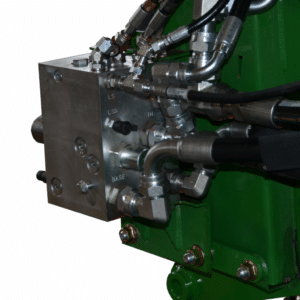

Leveling Manifold

Quality & Performance

27% Slope Compensation

- JH7020 Hillside for S660, S670, S760 & S770 Combines

- JH9020 Hillside for S680, S690, S780 & S790 Combines

- JH7110 Hillside for S7 600 & 700 Combines

- JH9110 Hillside for S7 800 & 900 Combines

Browse Components →

Click on image for more information.

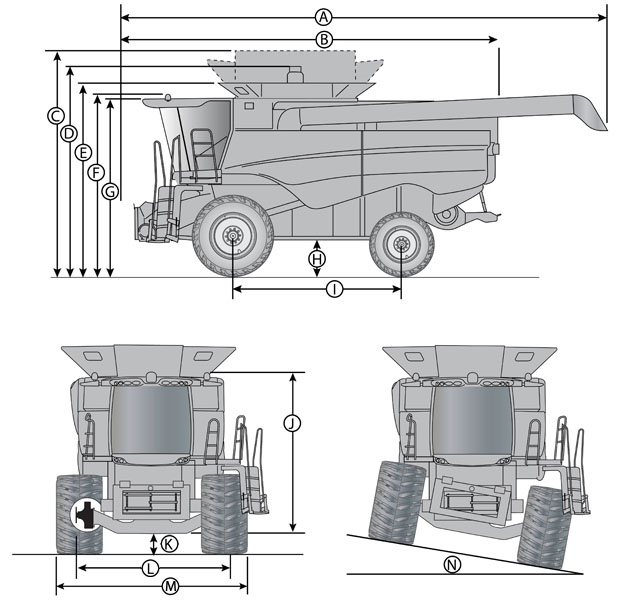

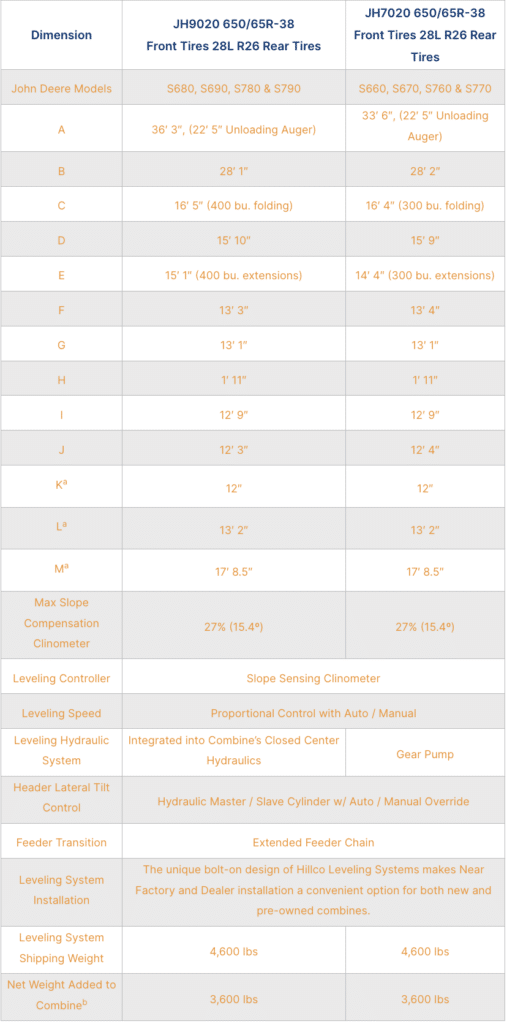

| Dimension |

JH9020 650/65R-38 Front Tires 28L R26 Rear Tires |

JH7020 650/65R-38 Front Tires 28L R26 Rear Tires |

|---|---|---|

| John Deere Models | S680, S690, S780 & S790 | S660, S670, S760 & S770 |

| A | 36′ 3″, (22′ 5″ Unloading Auger) | 33′ 6″, (22′ 5″ Unloading Auger) |

| B | 28′ 1″ | 28′ 2″ |

| C | 16′ 5″ (400 bu. folding) | 16′ 4″ (300 bu. folding) |

| D | 15′ 10″ | 15′ 9″ |

| E | 15′ 1″ (400 bu. extensions) | 14′ 4″ (300 bu. extensions) |

| F | 13′ 3″ | 13′ 4″ |

| G | 13′ 1″ | 13′ 1″ |

| H | 1′ 11″ | 1′ 11″ |

| I | 12′ 9″ | 12′ 9″ |

| J | 12′ 3″ | 12′ 4″ |

|

Ka |

12″ | 12″ |

|

La |

13′ 2″ | 13′ 2″ |

|

Ma |

17′ 8.5″ | 17′ 8.5″ |

| Max Slope Compensation Clinometer | 27% (15.4º) | 27% (15.4º) |

| Leveling Controller | Slope Sensing Clinometer | |

| Leveling Speed | Proportional Control with Auto / Manual | |

| Leveling Hydraulic System | Integrated into Combine’s Closed Center Hydraulics | Gear Pump |

| Header Lateral Tilt Control | Hydraulic Master / Slave Cylinder w/ Auto / Manual Override | |

| Feeder Transition | Extended Feeder Chain | |

| Leveling System Installation | The unique bolt-on design of Hillco Leveling Systems makes Near Factory and Dealer installation a convenient option for both new and pre-owned combines. | |

| Leveling System Shipping Weight | 4,600 lbs | 4,600 lbs |

| Net Weight Added to Combineb | 3,600 lbs | 3,600 lbs |

aDue to different tire configurations, row spacings, axle configurations, wheel offsets, axle positions and spindles types, machine widths will vary. Measurements given in chart are for minimum and maximum widths with single drive tires. For more detailed width information please contact Hillco.

bDue to different combine options weight will vary.

NOTE: Dimensions are approximate and subject to change without notice.

Why should you invest hard-earned dollars on a Hillco Leveling System for your combine? We believe you shouldn’t have to sacrifice your combine’s full potential just because you harvest in the hills.

Grain Savings

Increased Productivity – More Acres per Hour

Lower Operating Costs

Many harvesting expenses are related to the time it takes to harvest.

- Labor: shortening your harvest equals fewer man hours required for combine drivers and other harvest personnel.

- Fuel: shortening harvest time means harvesting equipment is running fewer hours.

- More time for more acres: The hours saved with the combine’s increased capacity in the hills means there is more time for more acres without having to purchase another combine.

- Get it in the bin: The longer the crop stands in the field the greater the exposure to weather and the risk of dry down. Being able to get the harvest out a week early can add tens of thousands of dollars to your bottom line.

Warranty Agreements

Fewer Combine Hours

Annual Cost of Ownership

Operator Comfort

Keeps Grain Tank Level

Easy Installation

Product and Customer Support

Frequently Asked Questions

What does a leveling system cost?

Where can I purchase a Hillco Leveling System?

Hillco Leveling Systems for John Deere combines are only available through authorized John Deere dealers. If your dealership is not already a Hillco dealer, have them contact Hillco and we will work towards establishing them as an authorized Hillco dealer. If you prefer to work through an established Hillco dealer please click on the Dealer Locator link or contact Hillco’s sales department. If you prefer to work through an established Hillco dealer, please contact Hillco’s Sales Department

If I have a Hillco Leveling System installed on my John Deere combine will it void the original combine warranty?

Can I install a Hillco Leveling System on a used John Deere S Series combine?

How are Hillco Leveling Systems installed on my combine?

New Combines: When purchasing a new combine our leveling systems are shipped from our manufacturing facility to our installation site near the John Deere Harvester Works combine plant. Upon your combine’s arrival at the installation site, a team of Hillco trained technicians professionally install the Hillco Leveling System onto your new combine. The installation includes a thorough two-part inspection; one completed by the installation team and the second provided by an independently trained inspector. After installation is complete, your new sidehill combine is shipped to your dealer. Upon arrival a third pre-field inspection is performed by your dealership.

Pre-Owned Combines: If you are purchasing a new or pre-owned combine already at your dealership or equipping your existing combine, installation can be easily performed by your local dealer. The “Bolt-On” design of Hillco Leveling Systems insures that your dealer’s trained technicians can complete a quality installation and final inspection on any model year S Series combine.

After Hillco Leveling Systems are installed, regardless of whether you have a new or pre-owned combine, you can be assured your leveling system will be delivered to you field-ready.