- All

- Blog

- News

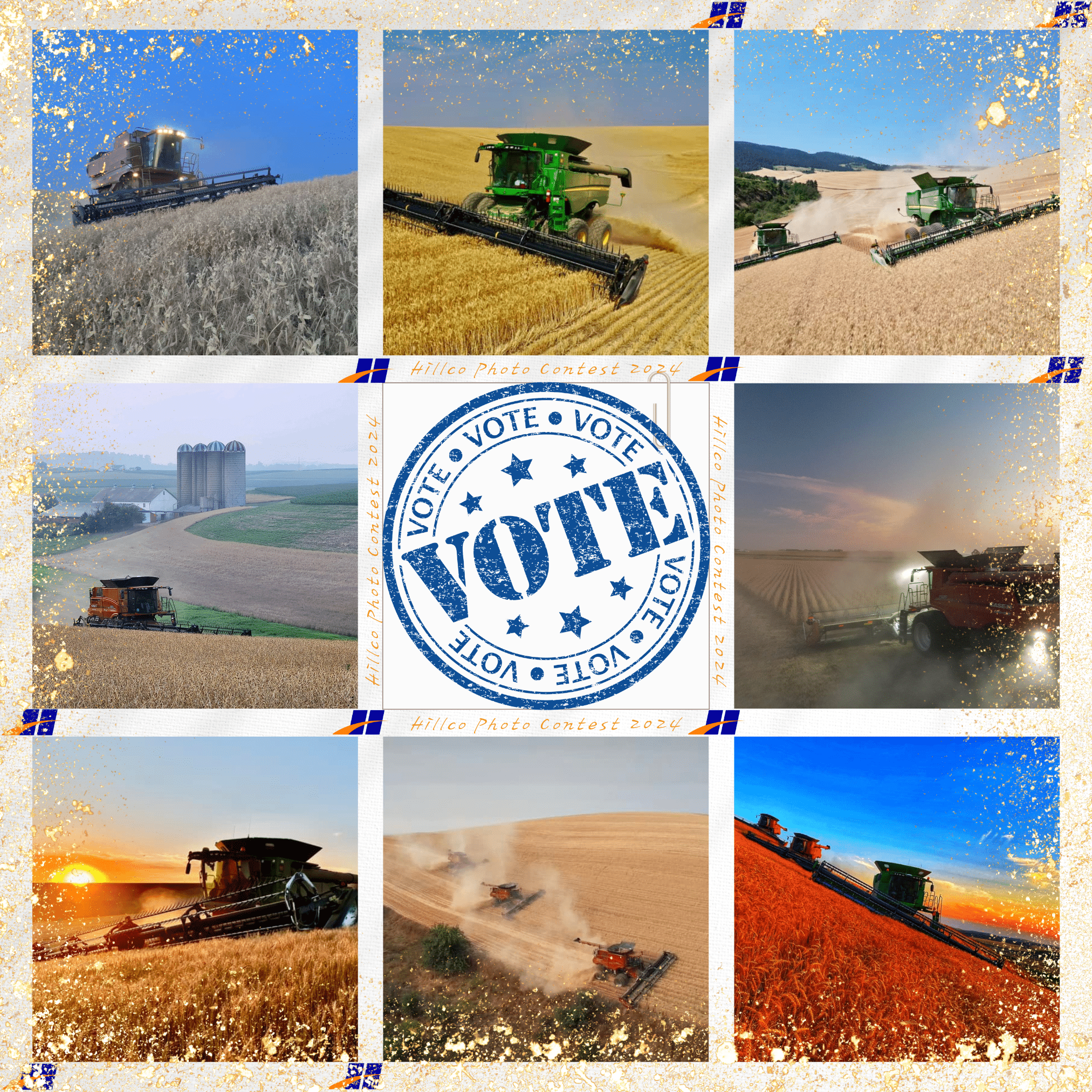

10+ Years, 100’s of Timeless Moments: Your Vote Decides the Victors!

October 16, 2024

No Comments

It’s that time of year again! The Hillco Technologies Annual Photo Contest is back, and this year we have enjoyed more than a decade of ...

Read More →

Maximizing Efficiency in Cattle Feeding Operations: The Importance of Hillco’s Wrap Twine Remover

September 30, 2024

No Comments

As cattle prices rise, efficient operations are crucial for profitability. In July, the average price for feeder steers at the Oklahoma City National Stockyards was ...

Read More →

Transforming Farm Operations with Hillco’s Air Flow System: Customer Testimonials

September 19, 2024

No Comments

In the agriculture industry, maintaining equipment and ensuring its optimal performance is crucial. Hillco Technologies’ Air Flow System has been a revolutionary product for many ...

Read More →

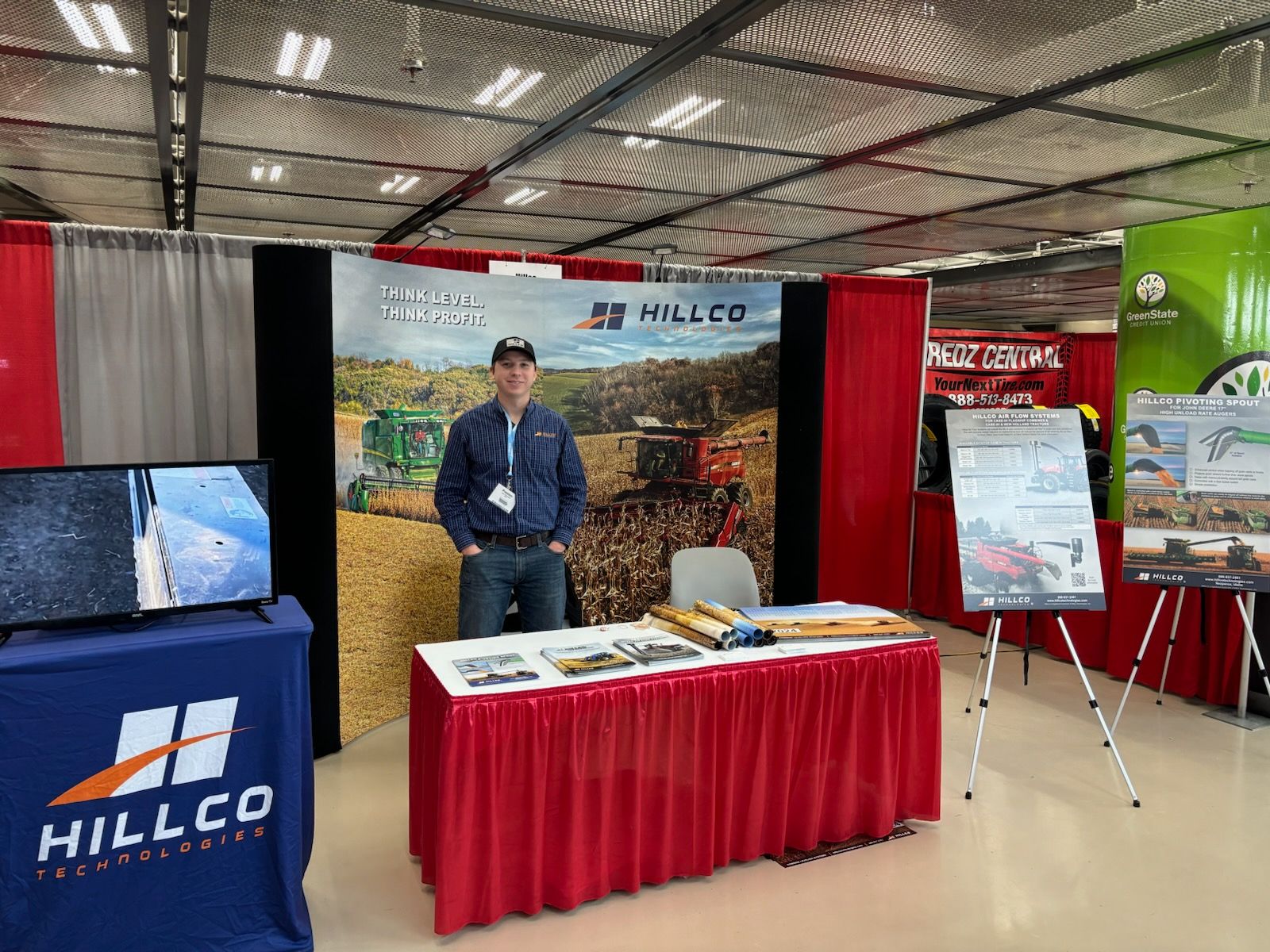

Hillco’s Innovations at Premier Agricultural Trade shows in 2025

September 3, 2024

No Comments

Hillco Technologies is preparing to make waves… …at some of 2025’s most prestigious agricultural expos and tradeshows. With a commitment to providing cutting-edge solutions that ...

Read More →

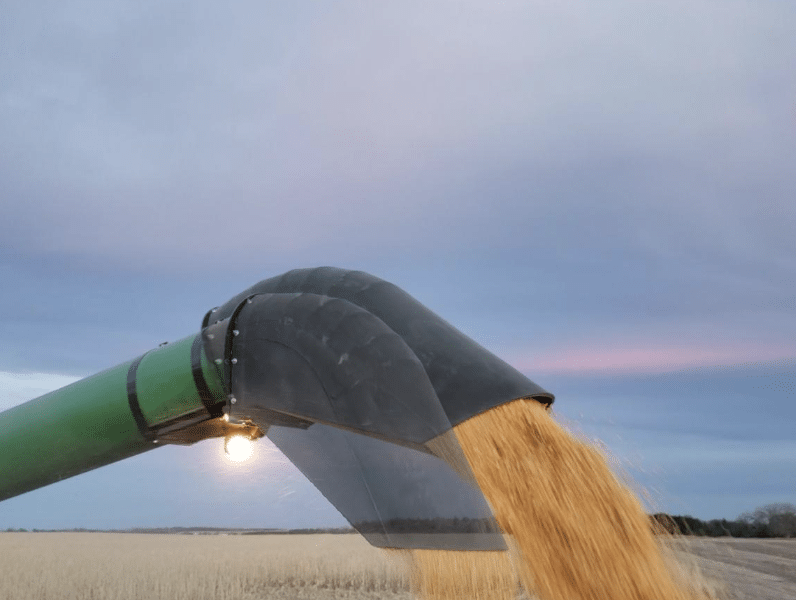

What’s Being Said About Hillco’s Pivoting Spouts?

July 16, 2024

No Comments

The Hillco Pivoting Spout allows 37° rotation which controls the grain stream better than stock spouts, allowing enhanced maneuverability when topping off grain trucks and ...

Read More →

Hillco Harrows & Holding Tanks

June 19, 2024

No Comments

Did you know… Each farming operation is unique, and Hillco’s Harrow and Spring Tooth Carts are designed accordingly- for versatile operations.A lesser-known fact about our ...

Read More →

The Rancher’s Plight: Plastic Disease in the Herd

June 17, 2024

No Comments

Overview The danger of plastic ingestion by cattle, specifically the risks associated with net wrapped hay bales, cannot be overstated. This condition, otherwise known as ...

Read More →

FAQs: Wrap Twine Remover (WTR)

June 4, 2024

No Comments

How many hydraulic remotes are needed to control the WTR? Just one remote or one third function is needed. We do not supply the two ...

Read More →

The Importance of Education

May 20, 2024

No Comments

Based in the small town of Nezperce, ID… The issue of educating our youth about local job opportunities holds immense significance here at Hillco Technologies. ...

Read More →

Community: Idaho Youth ChalleNGe Academy

May 20, 2024

No Comments

Sunny and sixties surrounded by mountain tops and lush greenery, we arrived in Pierce, Idaho to prepare for mock interviews at the Idaho Youth ChalleNGe ...

Read More →

Unveiling the Steaks: Diving into US Beef Production for National Beef Month

May 8, 2024

No Comments

Beef is not just a tasty morsel on dinner plates; it’s a cornerstone of American agriculture and culture. The United States is a powerhouse in ...

Read More →

Community: Job Fair in Kamiah, ID

April 18, 2024

No Comments

In a bustling high school gymnasium filled with anticipation and opportunity, students from across our community had the opportunity to explore potential career paths with ...

Read More →

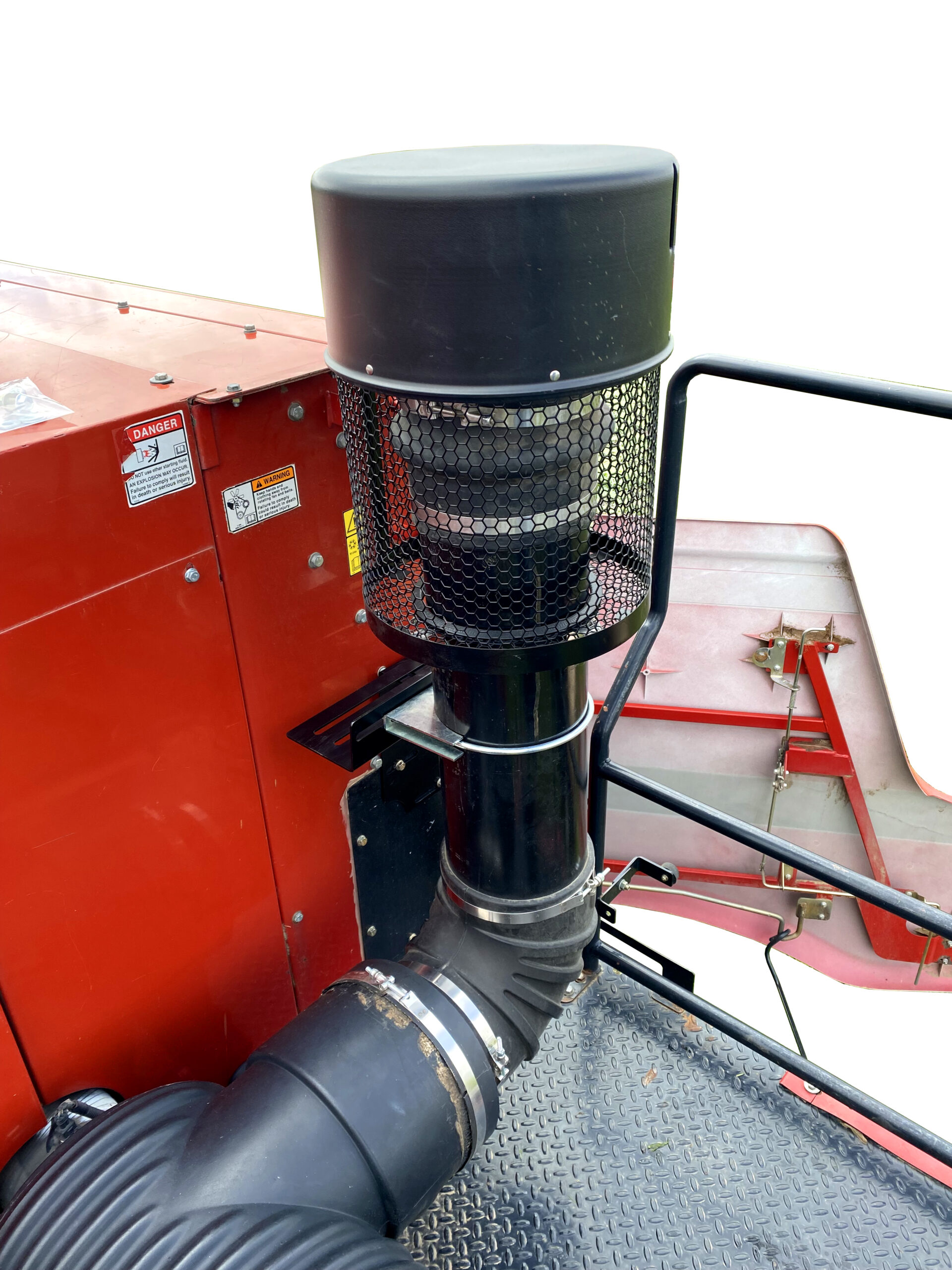

FAQs: Combine Air Flow Systems

April 15, 2024

No Comments

Getting fed up… …with constant clogs and looking to increase the useful life of your combine’s air filter, BUT want to know more before upgrading? ...

Read More →

FAQs: Wrap Twine Remover Bale Types

April 9, 2024

2 Comments

The only limit to our realization of tomorrow will be our doubts of today. Franklin D. Roosevelt As the Wrap Twine Remover continues its advance ...

Read More →

Hillco’s New Pivoting Spout: Case IH Combines

March 18, 2024

No Comments

Ask and you shall receive… Hillco Technologies has been inundated with questions regarding a pivoting spout for Case IH combines. This hype was the aftermath ...

Read More →

FAQs: Blade & Hooks of the Wrap Twine Remover

March 12, 2024

No Comments

The Wrap Twine Remover (WTR) from Hillco Technologies is gaining traction on the market. All this interest has spurred some conversations and customers have started ...

Read More →

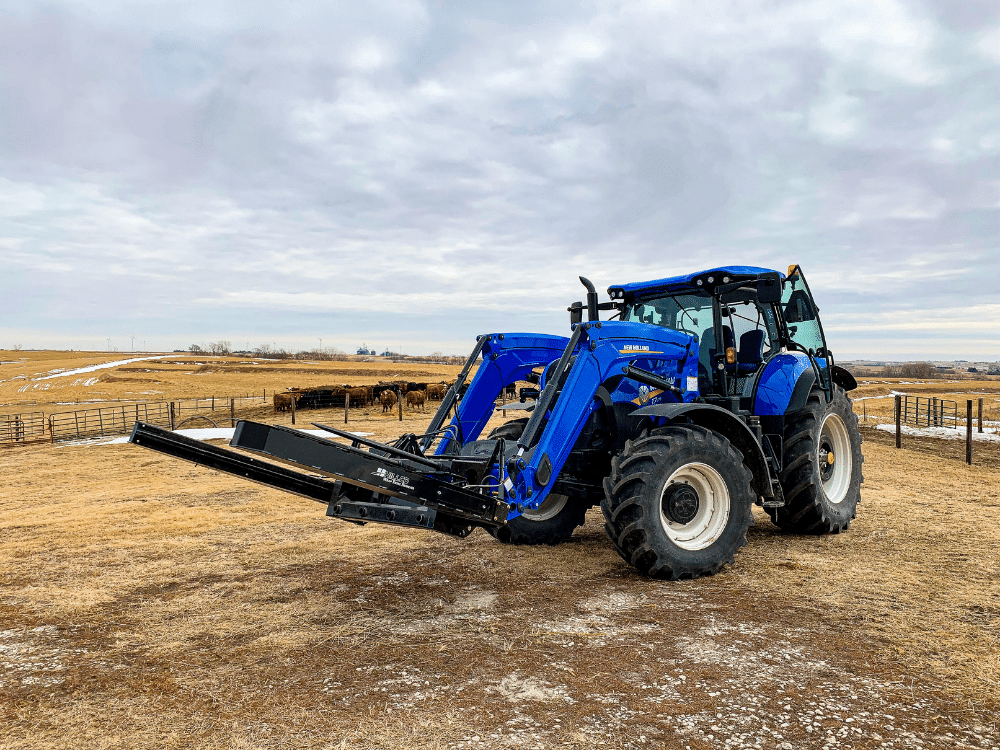

FAQs: Tractor Air Flow Systems

March 7, 2024

No Comments

Tired of constant clogs and looking to increase the useful life of your tractor’s air filter, BUT want to know more before upgrading? Here we ...

Read More →

Pivoting Spout: Comparison

February 27, 2024

No Comments

Adjustable auger spouts serve an irreputable purpose in the process of grain loading. With their growing popularity, additional manufacturers are entering the market. For anyone ...

Read More →

Ag Conference Attendance for 2024

February 14, 2024

No Comments

“Excuse me miss; may I make a suggestion?” I look up from rolling posters to find a kindly gentleman on the other side of our ...

Read More →

The Wrap Twine Remover: A Commitment to Safety

January 31, 2024

No Comments

We care about your safety! The Wrap Twine Remover (WTR) has taken the ranching industry by storm since its test-launch in 2021. It endured rigorous ...

Read More →

Food for Thought: Digestible Baling

January 18, 2024

No Comments

While the idea of digestible, ecofriendly baling presents several advantages, it is essential to acknowledge its limitations both in the context of wrapping hay bales ...

Read More →

Utilizing the Hillco Harrow in the Spring, Summer, and Fall

December 19, 2023

No Comments

Seasonality of agriculture equipment is a real thing. When considering a new purchase, of often high-ticket items, farmers weigh the pros and cons of just ...

Read More →

What’s Being Said about Hillco’s Air Flow Systems?

October 24, 2023

No Comments

Hillco Air Flow Systems for Case IH combines and Case IH and New Holland tractors are performing exceedingly well in the field. In the past ...

Read More →

Celebrating 30 Years of Collaboration: Case IH and Hillco Leveling Systems

August 23, 2023

No Comments

The partnership between Case IH and Hillco Technologies has been a transformative force in modern agriculture for the past three decades. This blog explores their ...

Read More →

Hillco Technologies Pivoting Spout

July 10, 2023

No Comments

What is the Hillco Pivoting Spout? The Hillco Pivoting Spout is an aftermarket attachment designed for John Deere combines. It enhances the unloading process by ...

Read More →

Hillco Wrap Twine Remover Benefits

June 1, 2023

No Comments

Hillco Wrap Twine Remover Cattle ranching has been an essential part of human civilization since the beginning of time. With advancements in technology, necessary daily ...

Read More →

The Importance Of Airflow

April 18, 2023

No Comments

Why are air filters important? Air filters are critical to the performance of combine and tractor engines. They prevent dirt, dust, and other particles from ...

Read More →

Harrow Cart Uses and Conditions

March 14, 2023

No Comments

What is the Hillco Harrow Cart? The Hillco Harrow Cart has been engineered and built with a durable design offering 16 bars of flexible harrow. ...

Read More →

Pivoting Spout- New and Improved

February 21, 2023

No Comments

What size combine does it fit on? The Hillco Pivoting Spout will fit any 17” high unload rate auger. You would also find them on ...

Read More →

Sidehill Vs. Hillside

January 3, 2023

No Comments

What is the difference between your Hillside and Sidehill Leveling Systems? The simple answer to the question is, the Sidehill will compensate for 18% slope ...

Read More →

Hillco Technologies – Through the Years

December 14, 2022

No Comments

What is Hillco Technologies? Hillco Technologies is an agriculture manufacturing company that provides innovative solutions. Read more about Hillco Technologies below. What sets Hillco apart? ...

Read More →

The Hillco AFS Corn Screen

November 15, 2022

No Comments

What are the benefits of the AFS Corn Screen? Prevents debris buildup which can cause precleaner plugging. Also helps improve the air flow system’s performance ...

Read More →

The Spring Tooth Harrow – Ease of Transportation

October 25, 2022

No Comments

What is the setup process of the Hillco Spring Tooth? The Hillco model can be hydraulically spread out and set up without getting out of ...

Read More →

The Dangers of Net Wrap Ingestion

September 20, 2022

No Comments

Can cattle eat net twine? Cattle cannot digest net wrap. It has a tendency to accumulate in the rumen over time. Most cattle will lose ...

Read More →

Hillco Harrow Cart – Raising the Bar on Spike Wear

August 2, 2022

No Comments

How durable are the spikes Hillco uses? Very durable. The Spike design offers heavy duty tooth bars and teeth made from high carbon steel. Why ...

Read More →

Not Your Grandfather’s Spring Tooth

July 22, 2022

No Comments

Is the Hillco Spring Tooth the same as all the others? The short answer is no, read below to find out the differences. What is ...

Read More →

Guide to Hillco Air Flow Systems

July 7, 2022

No Comments

How does the Hillco Air Flow System work? The Hillco kit will replace the stock intake on your Case IH or New Holland equipment. All ...

Read More →

Hillco Technologies, Inc. and John Deere introduce the Hillco Single Pass Round Bale System

May 25, 2022

No Comments

NEZPERCE, Idaho (August 21, 2014) – Hillco Technologies, Inc., working in developmental partnership with John Deere, has developed a revolutionary new system for harvesting corn ...

Read More →

Hillco Single Pass Round Bale System Review

November 7, 2014

No Comments

Quality. Efficiency. Sustainability. All in one round bale Tractor.com: Enter Hillco Technologies, Inc., a Nezperce, Idaho manufacturer well-known for its forage leveling systems. Through a ...

Read More →

Combining and baling in one pass

October 28, 2014

No Comments

Grainews: Joining forces with Hillco Technologies, Deere introduces a single pass round bale system designed to mate to a green combine. At the launch of ...

Read More →

Hillco Technologies wins Governor’s Award for Excellence in Agriculture

May 17, 2011

No Comments

Hillco Technologies, Inc. is proud to announce that it is the recipient of the 2011 Idaho Governor’s Award for Excellence in Agriculture in the Technical ...

Read More →

Leveling Systems Increase Harvest Productivity on Sidehills

April 11, 2011

No Comments

Farm Equipment Magazine: The desire for less grain loss and faster harvesting are putting sidehill leveling systems into the sales conversation throughout the Midwest.

Read More →